- OUR MACHINES

- Manual Shrink Wrapping Machines

- Semi-Automatic Shrink Wrapping Machines

- Fully Automatic Shrink Wrapping Machines

- Fully Automatic Side Seal Machines

- High Speed Fully Automatic Machines

- Shrink Tunnels

- Bundle (Sleeve Wrapper)

- Mailing Systems

- Carton Sealers / Carton Erectors

- Pallet Wrapping

- Vacuum Machines

- Roller Die Cutters

- Skin Machines

- Flow Wrap Machines

- Form Fill Seal Machines

- High Frequency Sealers

- Verticle Form Fill Sealing Machines

- Filling Machines

- Capping Machines

- Doy Pack Machines

- Over wrapping Machines

- Metal Detector and Check Weigher

- Labelling Machines

- Bagging Systems

- Top Seal Machines

- Seal Stretch Machines

- Blister Machines

- Horizontal Wrapping Systems

- Robotic Systems

- In Feed / Out Feed Conveyors

- PACKAGING FILMS

- Polyethylene

- Polyolefin

- BOPP Film

- Polypropylene

- PVC Films

- Stretch Films

- SECOND HAND MACHINES

- Second Hand Machines

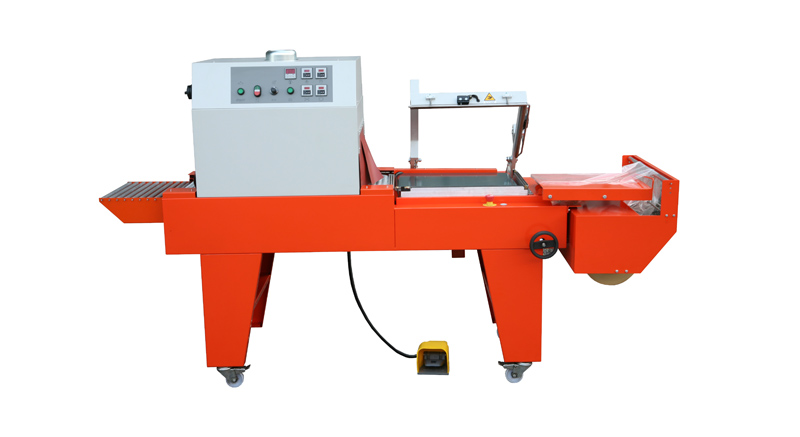

Shrink Wrapping Machine: Expert 5040

The Expert 5040 L-sealer line with two independent conveyors, is complete of sealing station and shrink tunnel, mounted on one metallic framework, treated and varnished with episodic powder.

Video: https://www.youtube.com/watch?v=EI5KZsogy5M&t=2s

Operation

After having set film position (acting on roll support) according to product dimensions, operator put product on working table under film and push same in sealing position. Sealing bar comes down automatically and seal film around product. Goods are than transported in tunnel, where a turbulence of hot air, shrinks film, until this assume form of product.

Machine suitable for half automatic packing of single or multi-products, using traditional heat sealable centrefold film. The model is manufactured in different sizes, takes small space, is practical in operation and absolutely reliable.

Main features

- Sealing bar adjustable in height with automatic pneumatic drive, controlled by foot pedal, or by push buttons or automatically by timer set cycle.

- Automatic unloading conveyor wire netting speed 7.5 mt/min.

- Tunnel conveyor zinc coated mesh, speed changer (inverter) from 3 to 10,5 mt/min.

- Safety stop on sealing bar down motion, should on its trajectory be an obstacle.

- Impulse type, timer controlled sealing. Bottom provided sealing blade.

- Tunnel electronic thermoregulator controlled air recycling.

- Shrink chamber in steel sheet, studied for a positive heat release of heating electric plugs (embodied in tube and provided with wings) and for a high air flow recirculation, for minimizing heat loss.

- Adjustable air flow with suitable shutters.

- Double insulation for best heat inside maintenance.

- Suitable centrefolded film: PVC, polypropylene, polyethylene.

- Products sizes max height 180 mm (given purely indicative because it depends from the characteristics of the product).

- Average output: from 200 to 900 pack/hour (given purely indicative because it depends from the characteristics of the product).

Optional

- Tunnel conveyor on application in stainless steel, or with rods of 10/15 mm diameter lined with rubber, or covered by a Teflon net.

- Straight or curved Unloading roller truck in different sizes.

- Tunnel opening height 450 mm.

- Electric production counter.

- Synchronized push buttons for bar start.

- Automatic trim recovery.

- Sealing with blade or wire on moving bar.

This machine comes in different sizes:

500mm X 400mm

750mm X 550mm

1150mm X 800mm

We can Custom make This Machine to YOUR specific REQUEST!