- OUR MACHINES

- Manual Shrink Wrapping Machines

- Semi-Automatic Shrink Wrapping Machines

- Fully Automatic Shrink Wrapping Machines

- Fully Automatic Side Seal Machines

- High Speed Fully Automatic Machines

- Shrink Tunnels

- Bundle (Sleeve Wrapper)

- Mailing Systems

- Carton Sealers / Carton Erectors

- Pallet Wrapping

- Vacuum Machines

- Roller Die Cutters

- Skin Machines

- Flow Wrap Machines

- Form Fill Seal Machines

- High Frequency Sealers

- Verticle Form Fill Sealing Machines

- Filling Machines

- Capping Machines

- Doy Pack Machines

- Over wrapping Machines

- Metal Detector and Check Weigher

- Labelling Machines

- Bagging Systems

- Top Seal Machines

- Seal Stretch Machines

- Blister Machines

- Horizontal Wrapping Systems

- Robotic Systems

- In Feed / Out Feed Conveyors

- PACKAGING FILMS

- Polyethylene

- Polyolefin

- BOPP Film

- Polypropylene

- PVC Films

- Stretch Films

- SECOND HAND MACHINES

- Second Hand Machines

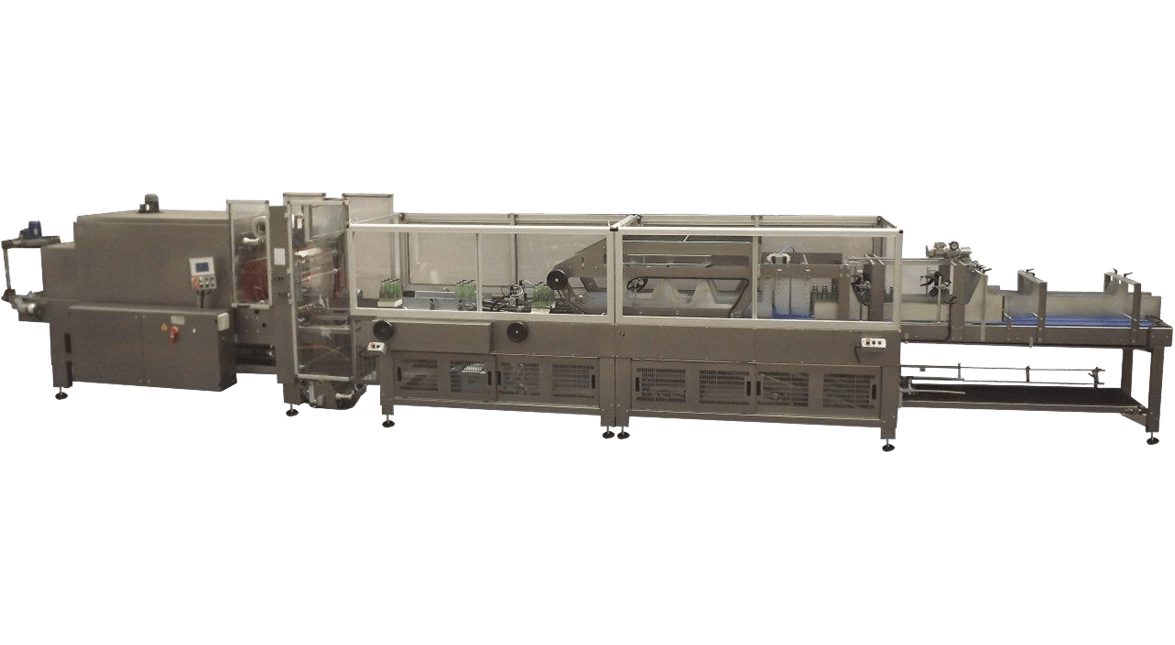

Bundle Machine Minipack 70 10 V

AUTOMATIC SEALING BAR SLEEVE WRAPPER WITH PLC, MULTILINE DIVIDER (6 TRACKS), AUTOMATIC LOADING OF CARDBOARD TRAYS OR FLAPS, TRAY FORMER

with 700 mm sealing bar