- OUR MACHINES

- Manual Shrink Wrapping Machines

- Semi-Automatic Shrink Wrapping Machines

- Fully Automatic Shrink Wrapping Machines

- Fully Automatic Side Seal Machines

- High Speed Fully Automatic Machines

- Shrink Tunnels

- Bundle (Sleeve Wrapper)

- Mailing Systems

- Carton Sealers / Carton Erectors

- Pallet Wrapping

- Vacuum Machines

- Roller Die Cutters

- Skin Machines

- Flow Wrap Machines

- Form Fill Seal Machines

- High Frequency Sealers

- Verticle Form Fill Sealing Machines

- Filling Machines

- Capping Machines

- Doy Pack Machines

- Over wrapping Machines

- Metal Detector and Check Weigher

- Labelling Machines

- Bagging Systems

- Top Seal Machines

- Seal Stretch Machines

- Blister Machines

- Horizontal Wrapping Systems

- Robotic Systems

- In Feed / Out Feed Conveyors

- PACKAGING FILMS

- Polyethylene

- Polyolefin

- BOPP Film

- Polypropylene

- PVC Films

- Stretch Films

- SECOND HAND MACHINES

- Second Hand Machines

Bundle Machine Minipack Wrapjet 20

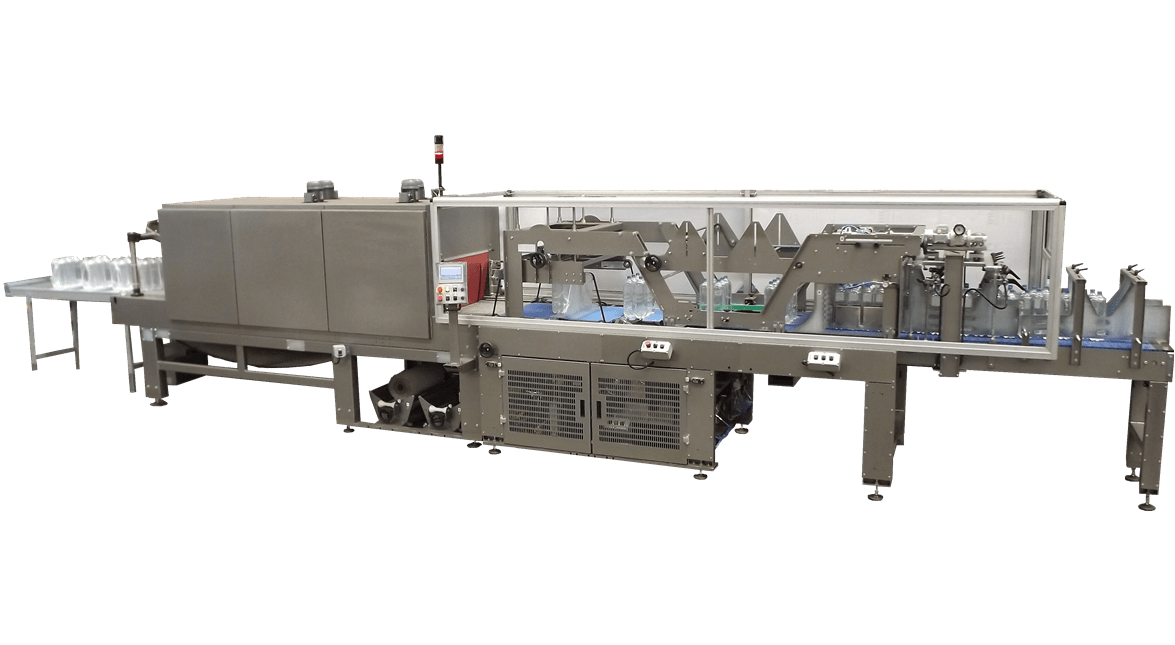

UTOMATIC SEAMLESS FILM SLEEVE WRAPPER WITH PLC AND MULTILINE DIVIDER (6 TRACKS)

bundle packaging in film only

- Seamless film machine without sealing bar

- Multi-row inline feeder

- Volumetric product sorting system

- System for wrapping the film around the package by overlapping the film under the package, which self-glues while going through the tunnel

- Film feeding and cutting unit with rotating blade

- Manual sealer for film splice

- Ionising bars to remove the electrostatic charge which accumulates in the film reels

- Heat-shrinking film reels with max diameter 400 mm – thickness between 50 and 100 microns

- Height of the worktop: 1000 +/-25mm

- Managed by PLC and TOUCH to change data and display the alarms for machine reset

- Real time monitoring of the alarms and direct editing of the machine settings with possibility of storing up to 10 formats

- The tunnel temperature is controlled by the PLC

- Heat-shrinking tunnel insulated with rock wool and heated with resistors. Forced ventilation with air circulation

- Heat-shrinking tunnel Length 1900 mm with air circulation system

- Internal conveyor belt in the heat-shrinking Tunnel, driven by a gear motor with adjustable speed and featuring a thin steel mesh grate with side chains

- Switch to change the cycle from automatic to manual

- Installed power 40kW

- Average electricity consumption is reduced by about 40% during normal operation

- Air consumption 80 nl/min

- Pneumatic components that work with non-lubricated dry air

- Machines compatible with Machinery Directive 2006/42/EC

For more information please contact us on (03) 9357-8400