- OUR MACHINES

- Manual Shrink Wrapping Machines

- Semi-Automatic Shrink Wrapping Machines

- Fully Automatic Shrink Wrapping Machines

- Fully Automatic Side Seal Machines

- High Speed Fully Automatic Machines

- Shrink Tunnels

- Bundle (Sleeve Wrapper)

- Mailing Systems

- Carton Sealers / Carton Erectors

- Pallet Wrapping

- Vacuum Machines

- Roller Die Cutters

- Skin Machines

- Flow Wrap Machines

- Form Fill Seal Machines

- High Frequency Sealers

- Verticle Form Fill Sealing Machines

- Filling Machines

- Capping Machines

- Doy Pack Machines

- Over wrapping Machines

- Metal Detector and Check Weigher

- Labelling Machines

- Bagging Systems

- Top Seal Machines

- Seal Stretch Machines

- Blister Machines

- Horizontal Wrapping Systems

- Robotic Systems

- In Feed / Out Feed Conveyors

- PACKAGING FILMS

- Polyethylene

- Polyolefin

- BOPP Film

- Polypropylene

- PVC Films

- Stretch Films

- SECOND HAND MACHINES

- Second Hand Machines

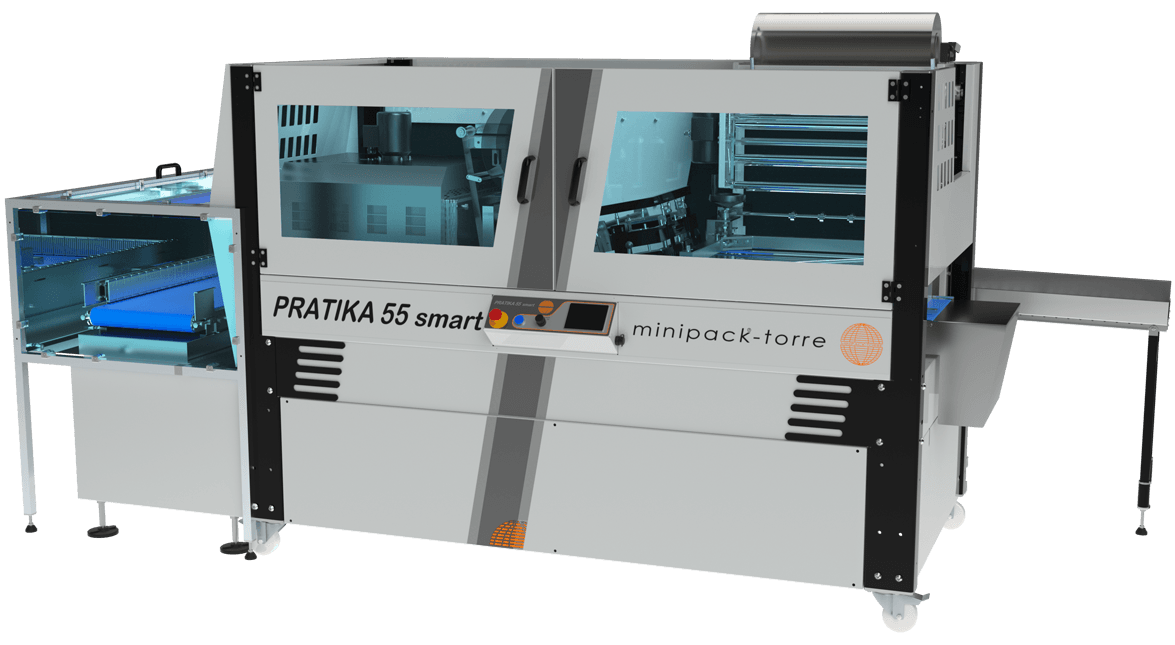

Shrink Wrapping Machine: Pratika 55 Smart

Pratika 55 Smart: the automatic monoblock shrink wrap machine.

The new version of the shrink wrap machine Pratika 55 Smart comes from a constant attention to the needs of the market, with the aim of proposing a technologically advanced product, but flexible and extremely compact. The included tunnel, revolutionary in the world of automatic machines, meets the space requirements, but above all reduces labour costs to a minimum, thanks to the patented option “come back” to a single operator.

Enhanced with strong technological, mechanical and electronic contents, the new Pratika 55 Smart represents a perfect synthesis of reliability, versatility and safety, by which the way of conceiving the shrink wrap machine with compact automatic operation evolves one more time.

Main features

L sealing system

Schneider Electric M221 PLC with 128 customisable and named programs

4.3 inch colour touch-screen control panel

USBand SD communication interface

Schneider Electric Brushless motor drive

Micro-perforation device with film tensioning adjustment on the set product height

Triangles and sealing bar with height adjustment

Sealing bar opening may be set on the touch-screen control panel

Belt speed (infeed/outfeed) adjustable by programmable Schneider Electric inverter model

Connectors for interfacing with supplementary unloading and loading belts

Standard belts compliant with the strictest regulations in force in the food sector (FDA) and completely antistatic

Motorised waste winder

Incorporated tunnel with reduced energy consumption

| Power Supply | 415 v |

| Phase | 3ph |

| Power Max | 7.5kw |

| Max Product Dimensions | 400x420x120h. |

| Machine Dimensions with Closed Hood | 2390x1190x1680h. mm |

| Machine Weight (Net/Gross) | 677 / 813 kg |